Many supplement brands and formulators today face growing demand for vegan products. Consumers increasingly look for clean, plant-derived ingredients that align with vegetarian or vegan lifestyles. Yet, when buyers see ingredients like microcrystalline cellulose (MCC) on a label, they often ask: “Is this truly vegan?” Without a clear answer, brands risk hesitation in formulation decisions, confusion during supplier selection, or worst — losing consumer trust once the product hits the shelf.

This concern is valid. Not all excipients are inherently plant-based, and the vegan claims of raw materials can impact labeling, certification, and global market acceptance. For brands targeting vegan, vegetarian, or plant-based markets, understanding the source and production of MCC is essential.

In this guide, U will learn what microcrystalline cellulose actually is, where it comes from, how it’s made, and whether it genuinely aligns with vegan product requirements. U will also get practical insights to help you communicate vegan compliance clearly to buyers and end consumers.

Microcrystalline cellulose is typically considered vegan because it is derived from purified plant cellulose — most often from wood pulp or cotton. The production process breaks down plant fibers into a fine, white powder that does not contain animal-derived components. When sourcing MCC, always confirm that the raw material and production process exclude animal derivatives, cross-contamination, or shared equipment with animal products. With proper supply chain transparency and certification, MCC can be confidently labeled vegan in dietary supplements, food, and cosmetic products.

To decide whether MCC fits your vegan positioning, it helps to understand what it is, how it’s sourced, and what standards matter for truly plant-based claims. The sections below guide you step by step.

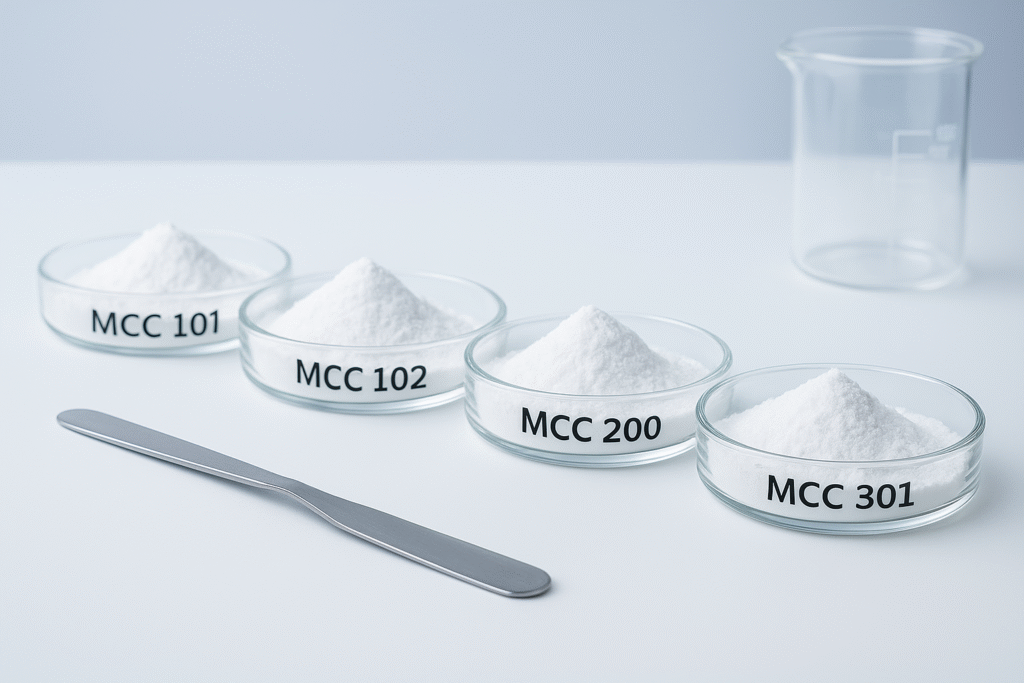

1. What Is Microcrystalline Cellulose?

Microcrystalline cellulose is a purified, fine white powder made by breaking down plant cellulose. It functions as a binder, filler, and flow agent in tablets, capsules, powders, and other solid dosage forms. It is also used in food, cosmetics, and industrial applications due to its neutral taste, chemical stability, and processing performance.

MCC is a plant-derived excipient made by purifying cellulose and converting it into a crystalline, inert powder useful in many formulations.

The base material for MCC is cellulose — the main structural component of plant cell walls. In commercial manufacturing, wood pulp or cotton linters (short fibers left after cotton ginning) are common sources. These raw materials are rich in cellulose and do not contain animal derivatives. After purification and controlled acid hydrolysis, the result is a fine, odorless powder with wide applications across industries.

Key Facts

| Attribute | Description |

|---|---|

| Source | Plant cellulose |

| Appearance | White, crystalline powder |

| Function | Binder, filler, flow aid |

| Solubility | Insoluble in water |

** MCC comes from plant-derived cellulose, making it inherently vegan in source.

** It performs key roles in formulation without active nutrition or animal content.

2. How Is MCC Produced and Why It Matters for Vegan Claims?

The production process affects whether an ingredient can truly be called vegan. Even plant-derived materials may come into contact with non-vegan substances during processing. Understanding how MCC is made helps U ensure its vegan status.

MCC is produced by purifying plant cellulose, typically using controlled acid hydrolysis and filtering. No animal-derived reagents are required in standard production.

- Raw Cellulose Extraction: Wood pulp or cotton linters are processed to extract pure cellulose.

- Acid Hydrolysis: Cellulose is partially broken down under controlled acid and heat.

- Neutralization and Washing: The resulting material is thoroughly washed to remove residues.

- Drying and Milling: The purified cellulose is dried and milled into fine particles.

Since the entire process uses plant material and typical reagents are inorganic acids and water, there are no intentional animal-derived inputs.

However, vegan integrity depends on sourcing and quality control — which we discuss next.

** Standard MCC production does not require animal materials.

** Vegan status depends on ingredient controls, not just source.

3. Common Plant Sources of MCC

Identifying sources is central to vegan certification. MCC manufacturers typically use wood pulp or cotton linters — both of which are plant materials.

MCC commonly comes from wood pulp or cotton linters, both considered vegan raw materials.

| Source Material | Description | Vegan Status |

|---|---|---|

| Wood Pulp | Cellulose from trees | Vegan |

| Cotton Linters | Cellulose from cotton ginning | Vegan |

These sources are free from animal derivatives. When processed in dedicated facilities with proper controls, the final MCC product can be marketed as vegan.

** Plant sources support vegan ingredient claims.

** MCC from certified raw materials helps maintain trust.

4. Potential Risks to Vegan Integrity in Manufacturing

Even plant-derived ingredients can face contamination risks if production lines also handle animal-based materials. Cross-contact, shared equipment, or certain chemical inputs can affect vegan certification.

Possible contamination risks include shared equipment, additives, and partial processing residues — all of which must be controlled for true vegan compliance.

Key risk areas include:

- Shared Equipment: If production lines also handle non-vegan ingredients.

- Additives: Certain processing aids or binders (rare in MCC) that might not be plant-based.

- Certification Gaps: Suppliers without vegan certification or traceability controls.

To avoid these risks, U should verify supplier quality systems, segregation protocols, and certification claims.

** Proper manufacturing hygiene prevents cross-contamination.

** Transparent supplier documentation supports vegan claims.

5. How to Verify Vegan Compliance in MCC Supply

Vegan claims are meaningful only when backed by traceability and certification. Confirming vegan compliance helps brands avoid consumer backlash and regulatory issues.

Verify vegan compliance through supplier documentation, audit reports, and third-party certification to ensure no animal derivatives or cross-contamination.

Steps to verify vegan compliance:

- Supplier Declaration: Written confirmation that raw materials and processes are free from animal-derived substances.

- Vegan Certification: Third-party certification (e.g., Vegan Society, V-Label).

- Traceability Records: Batch records showing source of cellulose and processing aids.

- Quality Audits: Onsite or remote verification of production lines.

These documents give buyers confidence and support product labeling in global markets.

** Verification builds consumer trust.

** Certification helps with global export compliance.

6. Why MCC Is Widely Used in Vegan Products

MCC fits vegan product trends because it supports clean labels, plant-based positioning, and consistent formulation performance. It enhances texture, improves flow, and provides stability in tablets, capsules, and powders without using animal-derived excipients.

MCC’s neutral sensory profile, plant origin, and functionality make it ideal for vegan supplements, food powders, and cosmetics.

Brand owners use MCC in a wide range of vegan products:

| Product Type | Benefit of MCC |

|---|---|

| Vegan Tablets & Capsules | Acts as binder and filler |

| Plant-Based Powders | Improves flow and mixing |

| Vegan Nuts & Bars | Enhances texture |

| Vegan Cosmetic Powders | Adds smooth finish |

Its neutral taste and stable chemistry allow MCC to integrate without altering flavor or performance.

** MCC supports multiple vegan product categories.

** Plant-based origin aligns with consumer expectations.

Conclusion

Microcrystalline cellulose is truly vegan when sourced from plant materials and manufactured in controlled environments without animal derivatives or cross-contamination. Its plant-based origin, stable performance, and broad functionality make MCC a smart choice for vegan supplements, food products, and clean-label cosmetics. To confidently label products as vegan, buyers should work with transparent suppliers who provide traceability, certifications, and production oversight.