A complete procurement guide for pharmaceutical, nutraceutical, and food manufacturers

Microcrystalline Cellulose (MCC) is one of the most widely used excipients in solid oral dosage forms. As a binder, filler, flow enhancer, and disintegrant, MCC plays a critical role in tablet hardness, compressibility, stability, and overall manufacturing efficiency. Because MCC performance varies significantly between grades and manufacturers, choosing the right supplier — and the right grade — is essential for achieving quality and consistency.

This Buyer’s Guide provides you with a clear, technical, and practical framework to evaluate MCC quality, select the correct grade, and assess supplier capabilities before purchase.

1. What Is Microcrystalline Cellulose (MCC)?

MCC is a purified, partially depolymerized cellulose produced from plant fiber. It is used widely as a compressible excipient in pharmaceuticals, dietary supplements, and food applications. With high stability, inertness, excellent binding ability, and superior flow properties, MCC is indispensable in both direct compression and wet granulation systems.

2. Key Applications Across Industries

Pharmaceutical Tablets & Capsules

- Direct compression tablets

- Wet granulation systems

- Filler/binder in capsules

- Controlled-release formulations

Nutritional Supplements

- Chewable tablets

- Effervescent tablets

- High-dose active ingredient tablets

Food & Beverage Products

- Anti-caking agent

- Texture modifier

- Fat replacer in low-calorie foods

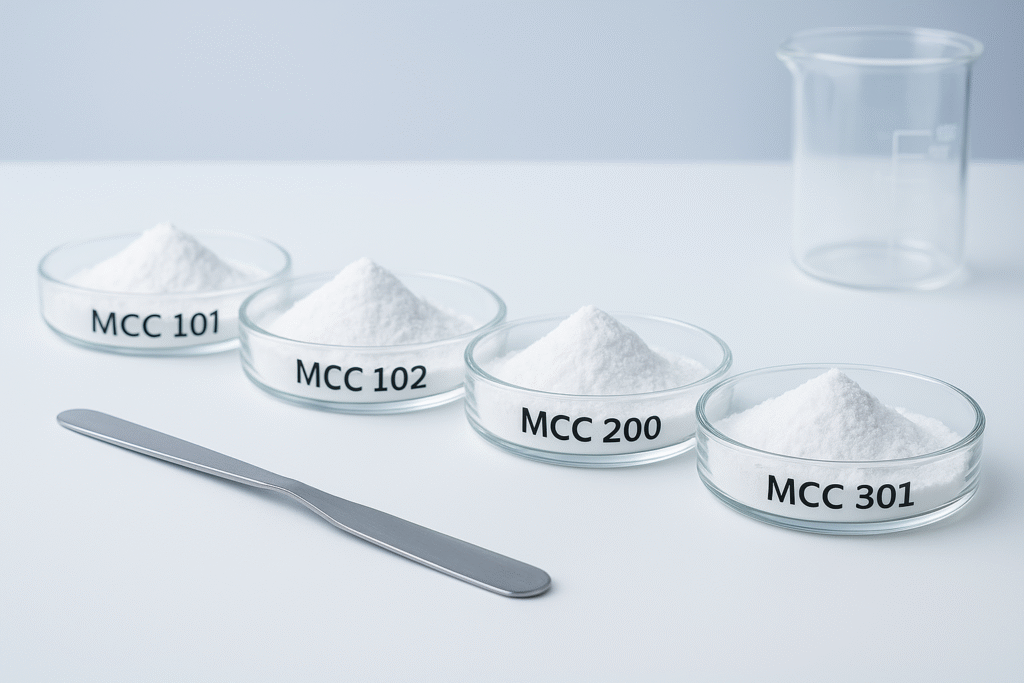

3. Understanding MCC Grades & How to Choose

MCC grades differ mainly in particle size, density, flowability, and compressibility.

MCC 101

- Fine particle size

- Strong binding properties

- Ideal for direct compression and chewables

MCC 102

- Larger particle size than 101

- Superior flowability for high-speed tableting

MCC 200

- Very high flowability

- Preferred for automated, continuous tableting lines

MCC 301

- Smart-density grade

- Excellent hardness at lower compression force

- Suitable for difficult-to-compress formulations

How to Select the Right Grade

| Requirement | Recommended Grade |

|---|---|

| High compressibility | MCC 101 / MCC 301 |

| High flowability | MCC 102 / MCC 200 |

| Low-dose API | MCC 101 |

| High-speed production | MCC 102 / MCC 200 |

| Improved tablet hardness | MCC 301 |

4. Technical Specifications to Evaluate Before Purchase

A professional buyer should always check the following parameters:

| Parameter | What It Indicates |

|---|---|

| Particle Size (µm) | Flowability, compressibility, blend uniformity |

| Bulk & Tapped Density | Tablet weight variation, die filling behavior |

| Moisture Content | Stability, flowability, microbial safety |

| pH | Compatibility with APIs and coating systems |

| Water Soluble Substances | Purity level |

| Loss on Drying | Storage stability |

| Microbial Limits | Safety & regulatory compliance |

Always request a COA + typical specification sheet before ordering.

5. Quality Control & Regulatory Requirements

Your MCC supplier should meet global regulatory standards.

Mandatory Certifications

- GMP

- ISO

- HALAL

- KOSHER

- Non-GMO

QC Practices You Should Expect

- Batch testing for moisture, purity, and density

- Laser particle size analysis

- Microbial testing

- Stability and compatibility evaluation

- Clear traceability for every lot

Reliable MCC quality ensures:

- Consistent tablet hardness

- Reduced production downtime

- Stable disintegration profile

- Regulatory compliance for global markets

6. How MCC Is Manufactured (What Buyers Should Know)

Professional MCC manufacturers use acid hydrolysis followed by:

- Neutralization

- Filtration

- Drying

- Milling

- Particle size classification

The consistency of these steps determines:

- Particle morphology

- Flow performance

- Batch uniformity

- Final product purity

Tip: Choose a supplier that controls the entire production chain — this ensures stable quality and competitive pricing.

7. Packaging & Storage Requirements

Standard Packaging

- 20–25 kg bags (paper bag or PP woven bag with inner liner)

Storage Conditions

- Cool, dry environment

- Keep sealed when not in use

- Protect from moisture and strong odors

Proper storage preserves flowability and prevents clumping.

8. How to Evaluate an MCC Supplier (Checklist)

Supplier Must-Haves

✔ GMP-certified manufacturing

✔ Full COA + MSDS + TDS

✔ Availability of multiple grades (101, 102, 200, 301)

✔ Stable factory capacity

✔ Proven export experience in regulated markets

Service Capabilities to Look For

✔ Customized particle size or density

✔ Technical support for formulation issues

✔ Quick sampling and batch consistency checks

✔ Fast global shipping and flexible MOQs

9. Why Choose Besty Pharma as Your MCC Supplier?

- Comprehensive Grade Portfolio: MCC 101, 102, 200, 301

- GMP & ISO Certified Manufacturing: Strict process control ensures batch consistency

- Customizable Specifications: Particle size, density, and moisture tailored to your formulation

- Technical Support: Assistance with direct compression, flowability challenges, and QC troubleshooting

- Global Supply Reliability: Stable production capacity and competitive lead times

- B2B-Focused Service: Perfect for pharmaceutical manufacturers, supplement brands, and contract manufacturers

10. Request Samples & Technical Data

We provide:

- Free samples

- COA, MSDS, TDS, and specifications

- Technical consultation for grade selection

Get in touch to select the ideal MCC grade for your formulations.